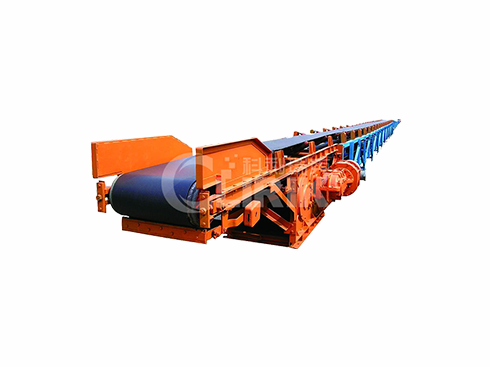

Belt conveyors have a simple structure and a large transport capacity and are mainly used to transport loose materials or piece items.

40 Years history production base and exporter

Pre-sale service

Pre-sale service

24 hours online

Free technical support and solutions

Factory visit anytime, free pick up

Sales service

Sales service

Commit to delivery fast

Provide On-site installation service

Free training of product operation

After-sales service

After-sales service

365 days after-sales online

Solve customer feedback problems timely.

Help customers optimize and upgrade equipment

Contact Us ( sales@clirik.com )

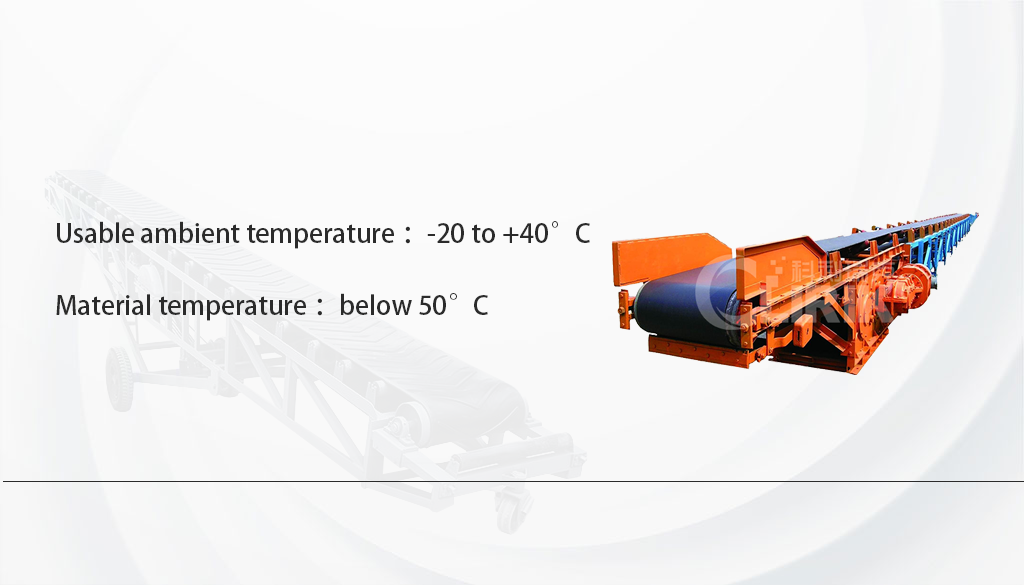

Our Belt Conveyor system is renowned for its high-capacity design, streamlined structure, and effortless maintenance, making it a staple in the transportation of bulk materials and finished goods. Employing standardized parts, it seamlessly integrates into various industrial applications, particularly in mining and metallurgy. The system is versatile, capable of operating as a standalone unit, in tandem with multiple conveyors, or in conjunction with other machinery to create horizontal or inclined transport setups.

The use of belt conveyors reduces the manual handling of materials. Consequently, large volumes of goods can be transported more efficiently, thereby allowing more cargo to be processed.

Less space and less people are needed to move items. Therefore, using belt conveyor to transport products between stations in production and processing lines is simple and efficient.

Belt conveyors can transport items of all shapes and sizes.

Protect products and materials from damage.

Conveyor belts consist of a loop or band of rollers connected to rotors, which are driven by a motor.

The motor on a conveyor belt actively drives the pulleys, which then initiates the belt's movement. Clirik maintain a sufficient level of friction between the belt and the pulleys to keep the belt securely in place. Furthermore, the motor's force effectively rotates the drive pulley, subsequently propelling the conveyor belt forward.

We strategically place pulleys at both ends of the conveyor belt and near the drive motor. The drive pulley, powered by a motor and reducer, moves the belt and has external bearings.

Additionally, return, idler, or tail pulleys guide the belt back to the drive pulley. With internal bearings, these are essential for tension maintenance, located either at the conveyor's end or both ends in a central drive setup.

Firstly, Clirik secure the conveyor belt with a dead plate inside its frame. Secondly, for the belt's return journey to the infeed, we position rollers both beneath and alongside the conveyor. Moreover, each roller features a spring-retained axle in the center shaft, making installation and removal a breeze.

On one hand, conveyor belts are offered in a multitude of types, sizes, shapes, angles, and materials, allowing for a tailored approach to various applications. Clirik select and design each conveyor belt to suit the system's needs, ensuring its functionality. On the other hand, Clirik engineer these belts to efficiently transport materials and products from one location to another.

| Belt Width (mm) | Length (m) Power (Kw) | Length (m) Power (Kw) | Length (m) Power (Kw) | Speed (m/s) | Capacity (t/h) |

| 500 | ≤12 3 | 12-20 4-5.5 | 20-30 5.5-7.5 | 1.3-1.6 | 78-191 |

| 650 | ≤12 4 | 12-20 5.5 | 20-30 7.5-11 | 1.3-1.6 | 131-323 |

| 800 | ≤6 4 | 6-15 5.5 | 15-30 7.5-15 | 1.3-1.6 | 278-546 |

| 1000 | ≤10 5.5 | 10-20 7.5-11 | 20-40 11-22 | 1.3-2.0 | 435-853 |

| 1200 | ≤10 7.5 | 10-20 11 | 20-40 15-30 | 1.3-2.0 | 655-1284 |

Shanghai CLIRIK Machinery Co.,Ltd. has been committed to the field of ultra-fine powder grinding machines for 20 years.

CLIRIK has a first-class manufacturing base with standardized and intelligent production lines.

CLIRIK's professional R&D, sales, installation and after-sales teams have provided door-to-door services to more than 100 countries and regions.

Should you have any questions, pls do not hesitate to contact us.

Phone: 0086-21-20236178; 86-13917147829

Email: sales@clirik.com

Website: https://www.grinding-equip.com

Address: No.19 Fuqing Rd, Pudong New Area, Shanghai201201, China.

Through long-term arduous technology research and international communication, our product quality has been in line with international level, winning a world-wide acclaim and honor, and our products are exported to ninety countries and regions like Tanzania, Nigeria, South Africa, Kenya, Turkey, Saudi Arabia, Philippines, Indonesia, Malaysia, Vietnam, Mexico, Brazil, Russia, Uzbekistan, Australia, etc.

Please feel free to write down your requirement in the form below.

We will reply you within 24 hours.

Copyright: Shanghai Clirik Machinery Co., Ltd.All rights reserved