The CLUM Series Ultrafine Vertical Roller Mill excels at processing ultrafine powders for white non-metallic minerals.

40 Years history production base and exporter

Pre-sale service

Pre-sale service

24 hours online

Free technical support and solutions

Factory visit anytime, free pick up

Sales service

Sales service

Commit to delivery fast

Provide On-site installation service

Free training of product operation

After-sales service

After-sales service

365 days after-sales online

Solve customer feedback problems timely.

Help customers optimize and upgrade equipment

Contact Us ( sales@clirik.com )

CLUM Series Ultrafine Vertical Roller Mill integrates grinding, grading, conveying, secondary powder selection and finished product packaging. The product fineness can reach 400-3000 mesh, breaking through the bottleneck of low ultrafine processing capacity.

We apply the Vertical Roller Mill extensively across various industries including chemicals, metallurgy, and non-metallic ores. It excels particularly in processing white superfine non-metallic ore powders, supplying high-quality fillers and additives for applications in paper making, coating materials, plastics, rubber, PVC, and printing ink. Our CLUM mill is also widely used to produce superfine dry powder of non-metal materials such as calcite, marble, limestone, dolomite, barite, talc, kaolin, wollastonite, gypsum, feldspar, and pyrophyllite.

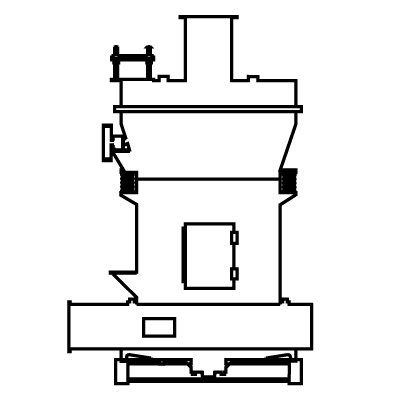

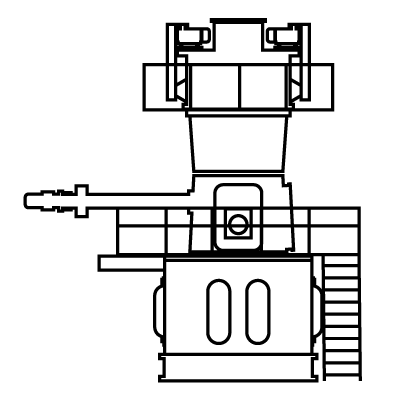

CLUM Series Ultrafine Vertical Roller Mill mainly consists of the motor, reduction gear, grinding rollers, grinding plate, pressure-applying device, classifier, mill body, oil station, and electrical system.

Main component for crushing and grinding materials. No power input when the grinding plate turn rotary, the rollers are rotated passively by friction force after touch the materials.

The area for grinding process, to be rotated and driven by reduction gear.

Control the grinding roller and plate gap, keep the roller pressure.

Multi-rotor classifier, utilize the rotated centrifugal force to separate the fine powder during the continuous process. It is a highly-efficient and energy-saving powder separating device.

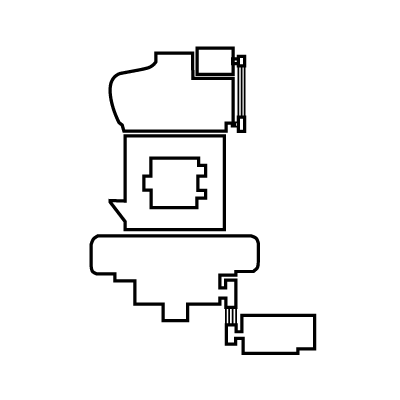

We use a spiral feeder to put materials into the central region of the CLUM series ultrafine vertical roller mill's grinding plate.

The mill's motor drives the reducer, which makes the grinding plate rotate. The rotation creates centrifugal force that pushes the materials to the plate's edge. In the grinding area, the roller's pressure crushes larger particles, while finer particles grind against each other to form a layer.

After grinding, the airflow guides the pulverized materials. It directs them to the edge of the grinding plate and into the powder selector. Inside the powder selector, blades separate the particles. They filter out coarse particles that don't meet the fineness specifications. These particles are sent back to the grinding plate. The particles that achieve the desired fineness are collected. They are gathered in the powder collector as the final product.

If there are impurities like iron blocks, their extra weight makes them fall into the mill's lower cavity as they near the edge of the grinding plate. To handle this, a scraper at the base of the grinding plate comes into play. It removes these impurities and directs them towards the discharging port. From there, they are efficiently expelled from the mill, ensuring the process continues smoothly.

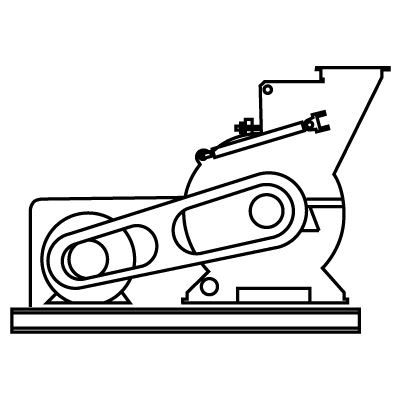

We feed raw materials from the hopper into the mill using a belt conveyor. The belt scale controls the weight of the materials, and the iron remover removes any tramp iron. Then, we send the materials to the elevator. They pass through an air lock valve and a screw conveyor before entering the mill for pulverization.

After pulverization, the powder classifier separates qualified powder, which we then send to a tank-type pulse dust collector. From there, a screw conveyor and a discharge valve transport the powder to the final product hopper. Finally, it's packed and sold directly.

Additionally, any coarse materials released by the mill unit are re-fed into the machine for further grinding.

The iron remover on the feeding belt conveyor ensures the safety of the ultrafine vertical roller mill's operation.

In certain specialized fields, there's a significant demand for high-quality powders, particularly in terms of their cut-off size and the percentage of 2μm content. To address this demand, we will add secondary or even tertiary classifier systems.

Central to our system is the ultra-fine classifier, which serves as the core equipment. Furthermore, we incorporate a buffering silo to temporarily store the powder, a bucket elevator to lift it to the next stage, and a blower to control the airflow. An air-proof discharging valve ensures controlled release of the powder, while pipes and ducts direct its flow throughout the system. A bag filter captures any oversized particles, and a screw conveyor moves the powder along. Finally, a pneumatic conveyor efficiently transports the powder to its destination. Together, these components form a comprehensive system designed to produce powders of the desired quality.

| Model|Item | CLUM1425 | CLUM1632 | CLUM1736 |

| Plate Diameters (mm) | 1400 | 1600 | 1700 |

| Number of rollers (pieces) | 3 | 3 | 3 |

| Number of classifier (pieces) | 6 | 6 | 8 |

| Power of classifier (Kw) | 6x15 | 6x22 | 8x22 |

| Main unit power (Kw) | 250 | 315 | 380 |

| Blower power (Kw) | 200 | 315 | 315 |

| Feed size (mm) | <10mm | <10mm | <10mm |

| Moisture of feeding material | <3% | <3% | <3% |

| Less than 2μm=34%output (t/h) | 9.5-11.5 | 12-14 | 14-16 |

| Less than 2μm=50%output (t/h) | 4.5-5.5 | 5.6-7 | 6.7-8.4 |

| Less than 2μm=70%output (t/h) | 1.5-2.5 | 1.9-3.2 | 2.3-3.8 |

Shanghai CLIRIK Machinery Co.,Ltd. has been committed to the field of ultra-fine powder grinding machines for 20 years.

CLIRIK has a first-class manufacturing base with standardized and intelligent production lines.

CLIRIK's professional R&D, sales, installation and after-sales teams have provided door-to-door services to more than 100 countries and regions.

Should you have any questions, pls do not hesitate to contact us.

Phone: 0086-21-20236178; 86-13917147829

Email: sales@clirik.com

Website: https://www.grinding-equip.com

Address: No.19 Fuqing Rd, Pudong New Area, Shanghai201201, China.

Through long-term arduous technology research and international communication, our product quality has been in line with international level, winning a world-wide acclaim and honor, and our products are exported to ninety countries and regions like Tanzania, Nigeria, South Africa, Kenya, Turkey, Saudi Arabia, Philippines, Indonesia, Malaysia, Vietnam, Mexico, Brazil, Russia, Uzbekistan, Australia, etc.

Please feel free to write down your requirement in the form below.

We will reply you within 24 hours.

Copyright: Shanghai Clirik Machinery Co., Ltd.All rights reserved