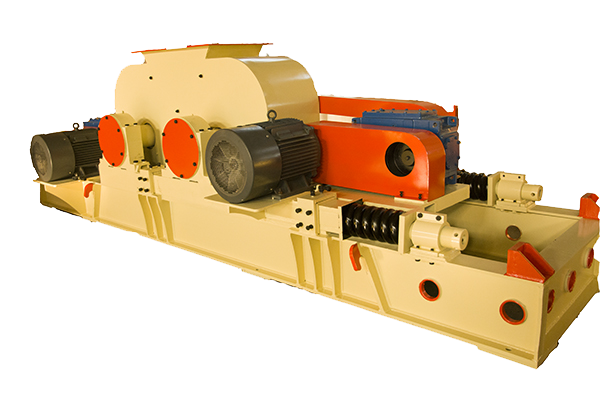

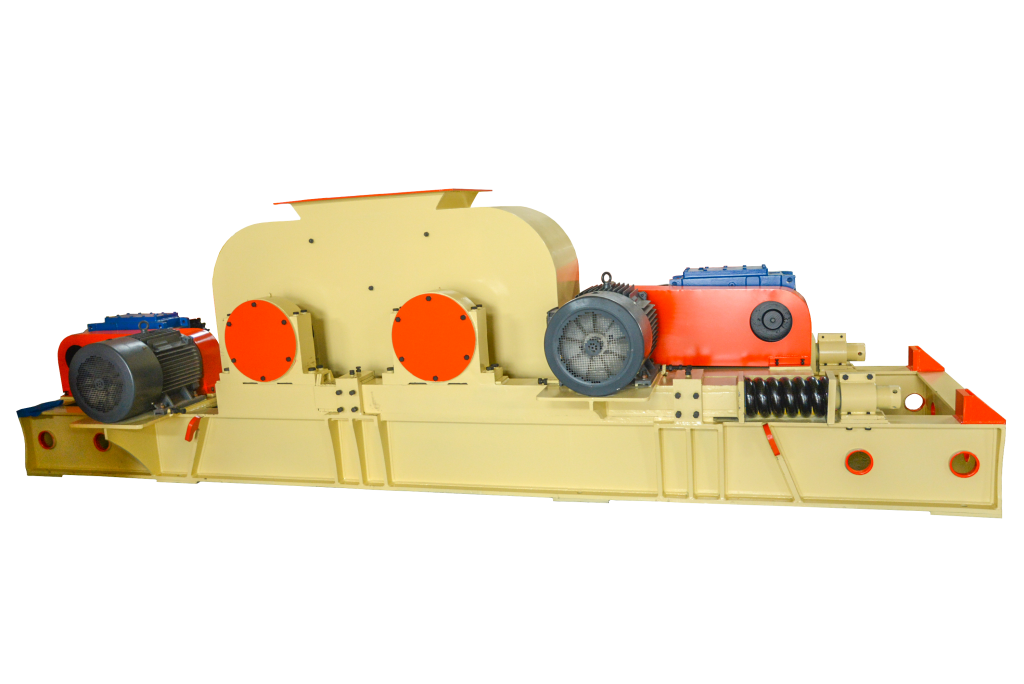

Double roller crusher is mainly used for medium and fine crushing of medium hardness materials such as limestone, coke and coal.

40 Years history production base and exporter

Pre-sale service

Pre-sale service

24 hours online

Free technical support and solutions

Factory visit anytime, free pick up

Sales service

Sales service

Commit to delivery fast

Provide On-site installation service

Free training of product operation

After-sales service

After-sales service

365 days after-sales online

Solve customer feedback problems timely.

Help customers optimize and upgrade equipment

Contact Us ( sales@clirik.com )

The Double Roller Crusher is a versatile machine, adept at crushing medium-hard materials across various industries such as cement, chemical, power, metallurgy, construction, and refractory materials. Furthermore, it efficiently handles materials like limestone, slag, coke, and coal. Additionally, it is suitable for both primary and secondary crushing tasks.

This crusher boasts a high reduction ratio and operates quietly.

Equipped with an overload protection system for reliable performance.

Delivers high efficiency with consistent particle size distribution.

The Double Roller Crusher is assembled with key components including the rollers, roller support bearings, compression and adjustment mechanisms, and the driving unit.

To achieve the crushing action, we operate the rollers at low speed and high pressure to squeeze the materials.

First, we feed materials vertically into the crushing chamber from the top of the machine, and then they are subjected to the intense pressure between the two rollers.

Next, the crushed materials are subsequently released due to gravity through the gap between the rollers.

Finally, we set the minimum gap between the rollers to determine the size of the discharged material.

Adjustment of the discharge size is managed by:

On the one hand, we position a wedge or gasket adjustment device between the two rollers. Initially, we pull the adjusting bolt at the top of the wedge device upward, causing the movable roller to separate from the fixed one, thereby increasing the gap and the discharge size. Conversely, when we push the adjusting bolt downward, this action reduces the gap and size.

On the other hand, we alter the discharge size by varying the number or thickness of the gaskets inserted into the gasket adjustment device.

| Type | Model | Input Size (mm) | Output Size (mm) | Capacity (m3/h) | Power (kw) | Dimension (mm) | Weight (kg) |

| Double Roll Mill | 2PGQ 610*400 | <36 | 2-9 | 3-9 | 22 | 1785*2365*1415 | 3800 |

| Double Roll Mill | 2PGQ 750*500 | <40 | 2-10 | 5-12 | 18.5*2 | 2720*2700*1400 | 10800 |

| Double Roll Mill | 2PGQ 750*700 | <40 | 2-10 | 6-16 | 22*2 | 2800*3987*1705 | 12200 |

| Double Roll Mill | 2PGQ 900*500 | <40 | 2-10 | 9-30 | 22*2 | 2750*1790*2065 | 15000 |

| Double Roll Mill | 2PGQ 900*900 | <40 | 2-10 | 11-45 | ~37*2 | 2750*2180*2065 | 16800 |

| Double Roll Mill | 2PGQ 900*1200 | <40 | 3-10 | 15-60 | ~55*2 | 2750*2480*2065 | 20800 |

| Double Roll Mill | 2PGY 1200*1000 | <40 | 3-12 | 10-50 | ~55*2 | 3690*3430*2700 | 46820 |

| Double Roll Mill | 2PGY 1200*1200 | <40 | 3-12 | 18-68 | ~75*2 | 3690*3630*2700 | 48600 |

| Four Roll Mill | 4PG 750*500 | 30-60 | 2-10 | 3-10 | 18.5+11/17 | 2760*3585*2650 | 19200 |

| Four Roll Mill | 4PG 900*700 | 40-100 | 2-10 | 16-20 | 30+12/24 | 3150*4175*3147 | 28700 |

| Four Roll Mill | 4PG 900*900 | 40-100 | 2-10 | 20-25 | 45x2 | 3150*2650*3147 | 31386 |

| Four Roll Mill | 4PGY 1200*1000 | 20-40 | 3-10 | 43-68 | 75+40/55 | 5410*5600*3600 | 67000 |

| Double-geared roller crusher | 2PGC 450*500 | 100-200 | 25-100 | 12-32 | <11 | 2260*2206*766 | 3100 |

| Double-geared roller crusher | 2PGC 600*750 | 300-600 | 50-125 | 50-75 | <22 | 3265*2850*1310 | 7400 |

| Double-geared roller crusher | 2PGC 900*900 | <800 | 75-150 | 60-110 | <30 | 3945*3405*1895 | 13670 |

| Double-geared roller crusher | 2PGC 920*1200 | <800 | 40-100 | 90-150 | <75 | 3848*3480*1394 | 16730 |

| Double-geared roller crusher | 2PGC 1200*1500 | <1000 | -100 | 150-250 | 2*55 | 8010*4050*2050 | 52000 |

Shanghai CLIRIK Machinery Co.,Ltd. has been committed to the field of ultra-fine powder grinding machines for 20 years.

CLIRIK has a first-class manufacturing base with standardized and intelligent production lines.

CLIRIK's professional R&D, sales, installation and after-sales teams have provided door-to-door services to more than 100 countries and regions.

Should you have any questions, pls do not hesitate to contact us.

Phone: 0086-21-20236178; 86-13917147829

Email: sales@clirik.com

Website: https://www.grinding-equip.com

Address: No.19 Fuqing Rd, Pudong New Area, Shanghai201201, China.

Through long-term arduous technology research and international communication, our product quality has been in line with international level, winning a world-wide acclaim and honor, and our products are exported to ninety countries and regions like Tanzania, Nigeria, South Africa, Kenya, Turkey, Saudi Arabia, Philippines, Indonesia, Malaysia, Vietnam, Mexico, Brazil, Russia, Uzbekistan, Australia, etc.

Please feel free to write down your requirement in the form below.

We will reply you within 24 hours.

Copyright: Shanghai Clirik Machinery Co., Ltd.All rights reserved