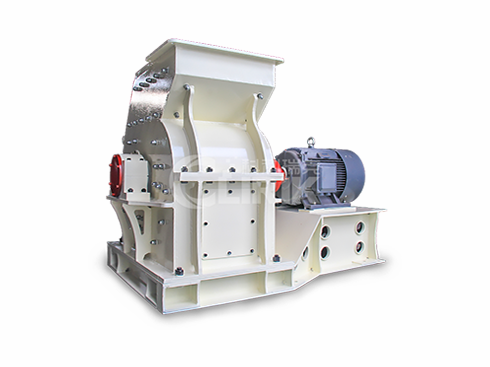

Hammer crusher is a device that uses the impact of high-speed rotating hammers to crush materials. It has high productivity and large crushing ratio.

40 Years history production base and exporter

Pre-sale service

Pre-sale service

24 hours online

Free technical support and solutions

Factory visit anytime, free pick up

Sales service

Sales service

Commit to delivery fast

Provide On-site installation service

Free training of product operation

After-sales service

After-sales service

365 days after-sales online

Solve customer feedback problems timely.

Help customers optimize and upgrade equipment

Contact Us ( sales@clirik.com )

The Hammer Crusher is a versatile crushing device that utilizes the impact of rotating hammers to process materials. It is widely utilized across various sectors including metallurgy, mining, chemical processing, cement production, construction, and the manufacturing of refractory and ceramic materials. This machine is adept at reducing both hard and soft ores into intermediate or smaller fragments, encompassing a spectrum of materials such as barite, limestone, gypsum, terrazzo, coal, slag, and more than a hundred different types.

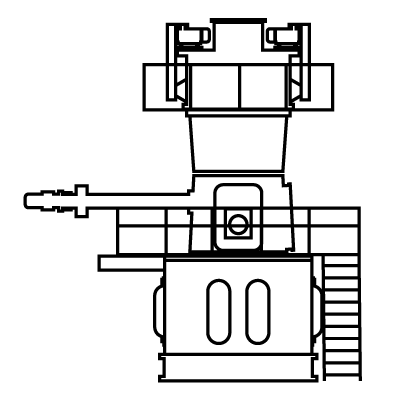

The Hammer Crusher is composed of a frame, rotor, support iron, and grate bars.

The frame is bifurcated into an upper and lower section, which are then joined by steel welding post-cutting. High manganese steel liners are installed within the frame and are replaced when they become worn out.

We design the rotors with a turn plate, pin shafts, and hammers, arranging them meticulously in a regular pattern around the main shaft. The rotors, driven by a motor, rotate swiftly within the crushing chamber, and the centrifugal force extends the hammers outward.

We feed materials into the machine through the feed opening. High-speed hammers strike, impact, cut, and grind the materials to reduce their size.

Firstly, the grate bars sift the crushed materials. Subsequently, materials that meet size standards pass through. Finally, larger materials stay for further processing.

We keep larger materials in the crushing chamber. They undergo further processing until they reach the desired size.

We adjust the final product's size by modifying the grate bars. This customization meets various specifications.

We tailor the clearance between the rotors and the grate bars. This allows for different product specifications.

| Model | PC400x300 | PC600x400 | PC800x600 | PC1000x800 |

| Rotor Diameter (mm) | 400 | 600 | 800 | 1000 |

| Rotor Width (mm) | 300 | 400 | 600 | 800 |

| r/min | 1100 | 1000 | 960 | 980 |

| Input Size (mm) | <100 | <220 | <350 | <400 |

| Output Size (mm) | 0-10 | 0-20 | 0-25 | 0-25 |

| Capacity (t/h) | 3-8 | 8-15 | 15-45 | 40-60 |

| Power (kw) | 11 | 18.5 | 45 | 75 |

| Hammer Number (pcs) | 16 | 20 | 28 | 30 |

| Weight (ton) | 0.5 | 1.6 | 4 | 6.5 |

| Dimension (mm) | 855*795*860 | 1150*1095*1230 | 2360*1490*1415 | 3072*1720*2121 |

Shanghai CLIRIK Machinery Co.,Ltd. has been committed to the field of ultra-fine powder grinding machines for 20 years.

CLIRIK has a first-class manufacturing base with standardized and intelligent production lines.

CLIRIK's professional R&D, sales, installation and after-sales teams have provided door-to-door services to more than 100 countries and regions.

Should you have any questions, pls do not hesitate to contact us.

Phone: 0086-21-20236178; 86-13917147829

Email: sales@clirik.com

Website: https://www.grinding-equip.com

Address: No.19 Fuqing Rd, Pudong New Area, Shanghai201201, China.

Through long-term arduous technology research and international communication, our product quality has been in line with international level, winning a world-wide acclaim and honor, and our products are exported to ninety countries and regions like Tanzania, Nigeria, South Africa, Kenya, Turkey, Saudi Arabia, Philippines, Indonesia, Malaysia, Vietnam, Mexico, Brazil, Russia, Uzbekistan, Australia, etc.

Please feel free to write down your requirement in the form below.

We will reply you within 24 hours.

Copyright: Shanghai Clirik Machinery Co., Ltd.All rights reserved