The HGM90 stone grinder has a high safety performance, and the fineness of the product can be adjusted between 325 and 2500 mesh.

40 Years history production base and exporter

Pre-sale service

Pre-sale service

24 hours online

Free technical support and solutions

Factory visit anytime, free pick up

Sales service

Sales service

Commit to delivery fast

Provide On-site installation service

Free training of product operation

After-sales service

After-sales service

365 days after-sales online

Solve customer feedback problems timely.

Help customers optimize and upgrade equipment

Contact Us ( sales@clirik.com )

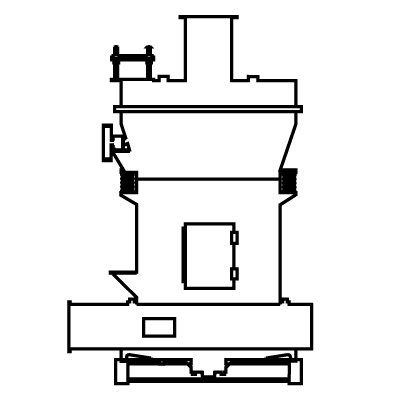

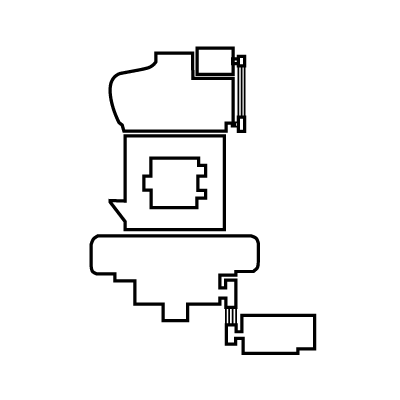

HGM90 stone grinder is a new type mining equipment for making micro powders, fine powders, widely used in metallurgy, mining, chemistry, cement, construction, refractory materials, ceramics, and other industries.

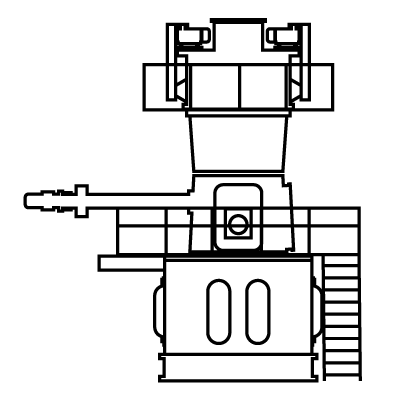

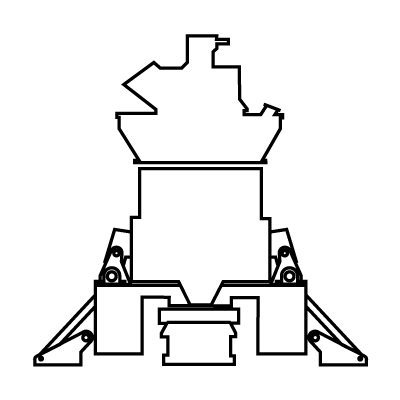

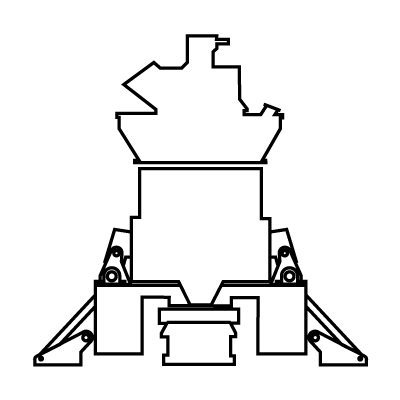

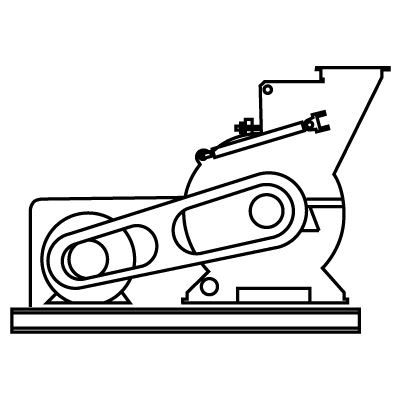

The HGM90 stone grinder production line includes hammer crusher, bucket elevator, storage hopper, vibrating feeder, main unit, inverter classifier, cyclone collector, pulse deduster system, high pressure positive blower, air compressors, and electrical control systems.

| ITEM | Number of roller | Layer of ring | Ring diameter | Feeding Size | Finished Size | Capacity | Overall Size |

| HGM90 | 24 | 3 | 900mm | ≤20mm | 47-5μm/325-3000mesh | 400-5500kg/h | 14.7x4.8x7.2m |

The electromotor drives the main bearing and dials via a reducer. Dials propel rollers within the ring using plungers.

The hammer crusher crushes materials into smaller pieces. The elevator transports these to the storage hopper.

The electromagnetic vibrating feeder and feeding pipe evenly deliver materials to the first dial's center.

Centrifugal force drives materials to the dial's edge. They fall into the ring, where rollers crush and grind them into powder after three rings.

The high-pressure centrifugal blower draws in air and propels crushed materials towards the classifier.

The rotating turbo in the powder concentrator separates coarse material for regrinding. Fine powder mixes with air and enters the cyclone.

The cyclone discharges fine powder into the bottom bin. The impulse duster purifies the air, and the blower and muffler expel it.

HGM90 stone grinder is mainly applied to non-inflammable, non-explosive, and brittle materials with Mohs hardness under six, such as calcite, chalk, limestone, dolomite, kaolin, gypsum, etc., totaling more than 100 kinds of materials. Product fineness can be adjusted between 325~2500 mesh.

Under the same final size and power, the product capacity of the ultrafine mill is twice that of jet mill and agitation mill.

The roller and ring are made of special material, significantly improving grinding efficiency. For the same material and final size, the lifetime of wearing parts can exceed one year, about 2-5 times longer than that of vertical shaft impact crusher and turbo-mill. Particularly when processing calcium carbonate and calcite, the lifetime can reach 2-5 years.

There are no rolling bearings and bolts in the grinding cavity, eliminating problems caused by bolt shedding or wear of bearings and seal components.

The product fineness can reach D97≤5μm.

The application of pulse dust collector and muffler reduce dust pollution and noise to meet national environmental protection standards.

Shanghai CLIRIK Machinery Co.,Ltd. has been committed to the field of ultra-fine powder grinding machines for 20 years.

CLIRIK has a first-class manufacturing base with standardized and intelligent production lines.

CLIRIK's professional R&D, sales, installation and after-sales teams have provided door-to-door services to more than 100 countries and regions.

Should you have any questions, pls do not hesitate to contact us.

Phone: 0086-21-20236178; 86-13917147829

Email: sales@clirik.com

Website: https://www.grinding-equip.com

Address: No.19 Fuqing Rd, Pudong New Area, Shanghai201201, China.

Through long-term arduous technology research and international communication, our product quality has been in line with international level, winning a world-wide acclaim and honor, and our products are exported to ninety countries and regions like Tanzania, Nigeria, South Africa, Kenya, Turkey, Saudi Arabia, Philippines, Indonesia, Malaysia, Vietnam, Mexico, Brazil, Russia, Uzbekistan, Australia, etc.

Please feel free to write down your requirement in the form below.

We will reply you within 24 hours.

Copyright: Shanghai Clirik Machinery Co., Ltd.All rights reserved