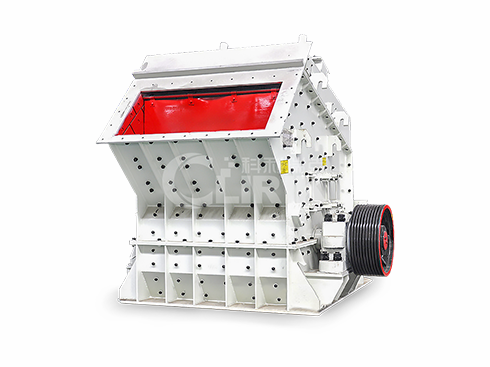

Impact crusher can produce cube-shaped high-quality powder, feed size up to 500mm, compressive capacity up to 360MPa.

40 Years history production base and exporter

Pre-sale service

Pre-sale service

24 hours online

Free technical support and solutions

Factory visit anytime, free pick up

Sales service

Sales service

Commit to delivery fast

Provide On-site installation service

Free training of product operation

After-sales service

After-sales service

365 days after-sales online

Solve customer feedback problems timely.

Help customers optimize and upgrade equipment

Contact Us ( sales@clirik.com )

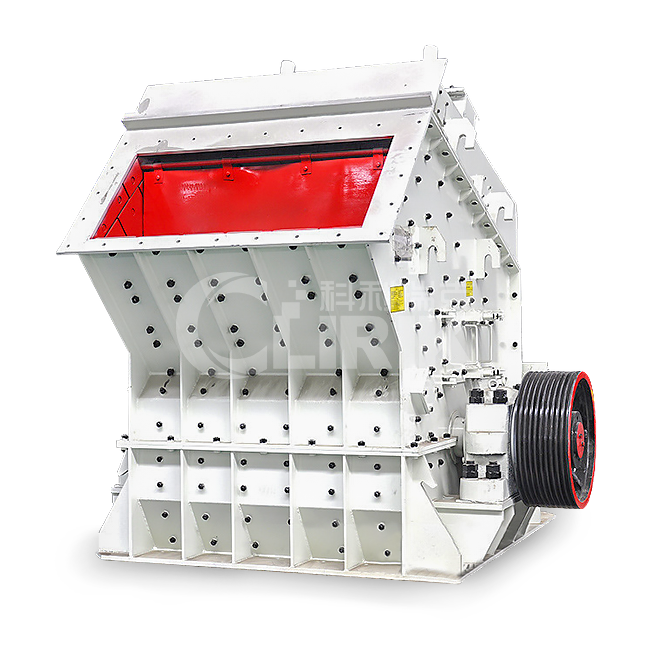

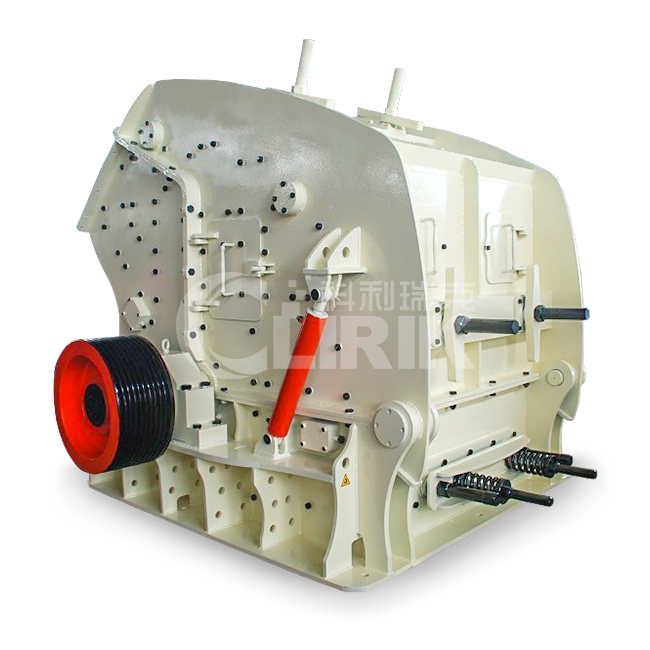

We specifically engineer our Impact Crusher to process materials with feed sizes up to 500mm and to crush with a strength of up to 360 MPa. Furthermore, a key benefit of this crusher is that we produce cubically shaped, high-quality finished powder that is free from tensile stresses and voids. Additionally, it finds extensive applications across mining, transportation, energy, construction, and chemical industries.

We craft hammers from high-chrome steel to ensure durability, while we make liner boards from wear-resistant materials.

The uniquely designed toothed impact plates are optimized for efficient crushing of hard rocks with minimal wear.

We design the material to bounce back from the impact liner into the influence of the blow bar until it is reduced to the desired size.

Furthermore, we simplify the overall crushing process, making it more streamlined and efficient.

The Impact Crusher operates on the principle of kinetic energy.

The motor drives the rotor to rotate at high speeds, and the installed blow bars strike the incoming material.

The blow bars exert a force that propels the material towards the surrounding impact devices.

Subsequently, the material bounces back from the impact liner into the influence of the blow bar until it is reduced to the desired size.

We make the gap between the impact rack and the rotor adjustable, which allows for customization of the final product's dimensions and shape.

| Model | Size (mm) | Feeder Size (mm) | Input Size (mm) | Capacity (t/h) | Motor (kw) | Weight (ton) |

| PF-0608 | Φ644x740 | 320x740 | ≤100 | 10-20 | 30 | 4 |

| PF-0807 | Φ850x700 | 400x730 | ≤300 | 15-30 | 30-45 | 8.13 |

| PF-1007 | Φ1000x700 | 400x730 | ≤300 | 15-60 | 37-55 | 9.5 |

| PF- 1010 | Φ1000x1050 | 400x1080 | ≤350 | 50-90 | 55-75 | 14 |

| PF- 1013 | Φ1000x1300 | 650x1350 | ≤350 | 80-120 | 90-110 | 12 |

| PF- 1210 | Φ1250x1050 | 400x1080 | ≤350 | 70-130 | 110-132 | 17 |

| PF- 1214 | Φ1250x1400 | 400x1430 | ≤350 | 90-180 | 132-160 | 22 |

| PF- 1315 | Φ1320x1500 | 860x1520 | ≤400 | 120-250 | 180-260 | 26 |

| PF-1320 | Φ1320x2000 | 860x2030 | ≤500 | 160-350 | 300-375 | 30 |

Shanghai CLIRIK Machinery Co.,Ltd. has been committed to the field of ultra-fine powder grinding machines for 20 years.

CLIRIK has a first-class manufacturing base with standardized and intelligent production lines.

CLIRIK's professional R&D, sales, installation and after-sales teams have provided door-to-door services to more than 100 countries and regions.

Should you have any questions, pls do not hesitate to contact us.

Phone: 0086-21-20236178; 86-13917147829

Email: sales@clirik.com

Website: https://www.grinding-equip.com

Address: No.19 Fuqing Rd, Pudong New Area, Shanghai201201, China.

Through long-term arduous technology research and international communication, our product quality has been in line with international level, winning a world-wide acclaim and honor, and our products are exported to ninety countries and regions like Tanzania, Nigeria, South Africa, Kenya, Turkey, Saudi Arabia, Philippines, Indonesia, Malaysia, Vietnam, Mexico, Brazil, Russia, Uzbekistan, Australia, etc.

Please feel free to write down your requirement in the form below.

We will reply you within 24 hours.

Copyright: Shanghai Clirik Machinery Co., Ltd.All rights reserved