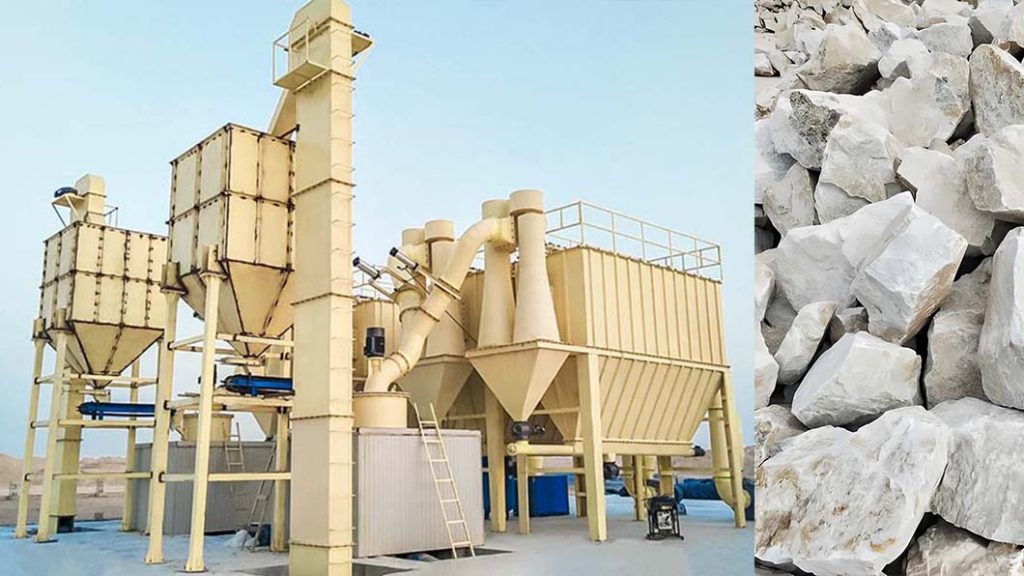

In the ever-evolving world of industrial technology, the HGM Grinding Mill has emerged as a revolutionary tool in the limestone processing industry. This state-of-the-art mill offers a highly efficient and precise method for converting raw limestone into fine powder, a critical component in a wide range of industrial applications. The HGM Grinding Mill's innovative design and advanced technology have set a new benchmark for efficiency and quality in the processing of limestone.

The process starts with the careful placement of limestone into a hopper, a temporary storage unit that holds the material before it is fed into the grinding chamber. The hopper is designed to ensure that the limestone is fed into the mill in a controlled manner, thanks to the feeder, a sophisticated mechanical device that regulates the flow of material. This feeder ensures that the limestone is delivered to the grinding chamber at an optimal rate, preventing any potential issues that could arise from overloading or underfeeding.

Inside the grinding chamber, the HGM Grinding Mill's rollers apply immense pressure to the limestone, crushing it into smaller pieces and then grinding it into fine powder. The grinding chamber is meticulously engineered to ensure that the limestone is processed uniformly, maximizing the efficiency of the grinding process. This uniform processing is crucial for maintaining the high quality of the final product.

After the limestone has been ground into fine powder, it is carried away from the grinding chamber by a carefully controlled airflow. This airflow is designed to efficiently transport the powder without causing any loss of material. The powder-laden air then moves to a classifier, a sophisticated device that separates the powder based on its fineness. The classifier uses a combination of centrifugal force and gravity to distinguish between fine and coarse particles, ensuring that only the finest powder meets the required specifications.

The fine powder is directed to a cyclone collector, a cylindrical device that uses centrifugal force to separate the powder from the airflow. As the air swirls inside the collector, the fine powder particles are forced to the outer walls and collected at the bottom. Meanwhile, any coarse particles that do not meet the fineness criteria are identified by the classifier and returned to the grinding chamber for regrinding. This regrinding process ensures that all limestone material is eventually ground to the desired fineness, maximizing the efficiency of the entire operation.

Once the fine powder has been collected, it is transferred to the packaging area. Here, the powder is carefully packaged to ensure its quality and integrity are maintained during storage and transportation. The final product, now ready for use, is a testament to the efficiency and precision of the HGM Grinding Mill.

The HGM Grinding Mill represents a significant advancement in limestone processing technology. Its ability to transform raw limestone into fine powder with such precision and efficiency is a testament to the power of innovation. As industries continue to demand high-quality limestone powder, the HGM Grinding Mill is poised to meet those needs, driving progress and ensuring that the future of limestone processing is both bright and efficient.

Please feel free to write down your requirement in the form below.

We will reply you within 24 hours.

Copyright: Shanghai Clirik Machinery Co., Ltd.All rights reserved