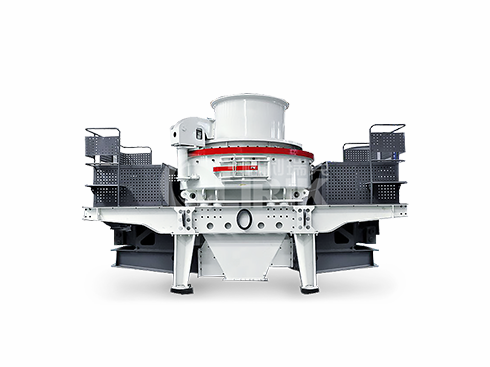

Vertical Impact Crusher is mainly used for crushing and shaping soft, medium-hard and extremely hard materials.

40 Years history production base and exporter

Pre-sale service

Pre-sale service

24 hours online

Free technical support and solutions

Factory visit anytime, free pick up

Sales service

Sales service

Commit to delivery fast

Provide On-site installation service

Free training of product operation

After-sales service

After-sales service

365 days after-sales online

Solve customer feedback problems timely.

Help customers optimize and upgrade equipment

Contact Us ( sales@clirik.com )

Optimizing the crushing chamber structure, we enable the Clirik Vertical Shaft Impact Crusher to stand as a premier choice for artificial sand production. It excels in crushing and shaping a wide range of materials, from soft to hard. Furthermore, we have extensively applied this equipment in processing ores, refractory materials, bauxite, abrasives, glass materials, construction materials, and various metal ores, leveraging its proven performance over more than three decades. Notably, this equipment distinguishes itself as the preferred machine for handling the most challenging and hard materials.

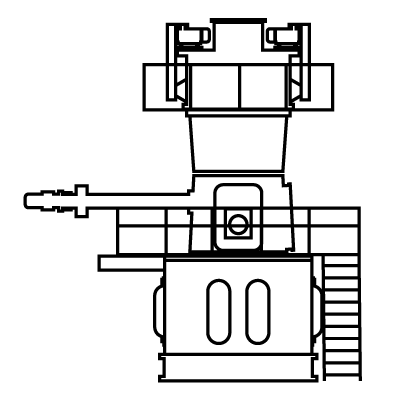

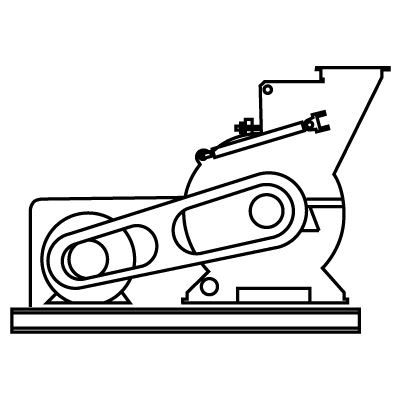

We optimize the crushing chamber structure to enable rapid conversion between rock-on-rock and rock-on-iron crushing modes.

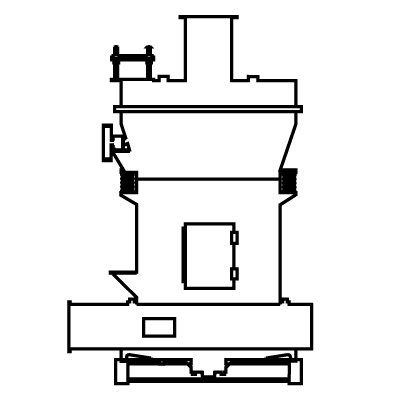

Key components such as the impeller, bearing cylinder, and lower body are of a completely new design.

The guardrail height is lowered to avoid interference when the feed hopper is swung open. The humanized design facilitates the maintenance of the impeller and bearing cylinder.

In the Vertical Shaft Impact Crusher, the crushing process mimics stone-on-stone impact. Materials descend into the impeller cavity where, driven by significant centrifugal force, they actively collide with downward-moving material. These collisions create a vortex between the impeller and the shell, leading to multiple impacts. Eventually, the reduced stones exit and are directed to a vibrating screen. There, suitable materials are guided to a sand washing machine, while oversized materials are recycled back into the sand maker for further reduction. The output sizes can be tailored to meet customer specifications. Should the input material exceed the designed size, additional crushing equipment may be necessary.

| Model | Inout Size (mm) | Power (kw) | Speed (r/min) | Capacity (t/h) | Dimension (mm) | Weight (kg) |

| PCL-600 | 35 | 22-55 | 2000/3000 | 12-30 | 2500*Φ1600*2260 | 5600 |

| PCL-750 | 45 | 45-90 | 1500/2500 | 25-55 | 2780*Φ1800*2700 | 7300 |

| PCL-900 | 50 | 90-180 | 1200/2000 | 55-100 | 3900*Φ2160*2770 | 12100 |

| PCL-1050 | 60 | 150-264 | 1000/1700 | 100-160 | 4660*Φ2450*3660 | 16900 |

| PCL-1250 | 60 | 264-440 | 850/1450 | 160-300 | 5600*Φ2950*4000 | 22000 |

| PCL-1350 | 60 | 320-440 | 800-1193 | 200-360 | 5340*Φ2940*3650 | 26000 |

Generally speaking, there are many factors that affect the production capacity of impact crusher. Generally speaking, there are five factors. Below I will describe these five factors and propose corresponding solutions.

The hardness of materials plays a crucial role in the sand-making process. Harder materials not only slow down the process but also lead to significant wear on the equipment. This results in a lower production rate and reduced capacity. Therefore, careful material selection is essential to ensure efficient sand-making operations.

The composition of materials before entering the impact crusher is another critical factor. Materials with a high content of fine powder can negatively impact sand-making due to their tendency to adhere and interfere with transportation. To mitigate this, materials with excessive fine powder should be pre-screened to remove as much fine powder as possible, ensuring the normal operation of the impact sand-making machine.

The fineness of materials after being crushed by the impact crusher is also a significant consideration. There is an inverse relationship between the fineness requirement and the sand-making capacity; the finer the material, the lower the capacity. The specific requirements will dictate the fineness setting, but if no special demands exist, a medium fineness is typically sufficient.

High viscosity materials tend to adhere more, potentially causing buildup inside the impact crusher's sand-making chamber. This can decrease efficiency and impede machine operation if not managed. Selecting materials with lower viscosity is advisable for smooth sand-making processes.

Excessive material humidity directly affects sand-making by causing adhesion and blockages, thus reducing output. Strict humidity control is essential, with drying methods like sun or air drying used to manage high moisture levels.

Shanghai CLIRIK Machinery Co.,Ltd. has been committed to the field of ultra-fine powder grinding machines for 20 years.

CLIRIK has a first-class manufacturing base with standardized and intelligent production lines.

CLIRIK's professional R&D, sales, installation and after-sales teams have provided door-to-door services to more than 100 countries and regions.

Should you have any questions, pls do not hesitate to contact us.

Phone: 0086-21-20236178; 86-13917147829

Email: sales@clirik.com

Website: https://www.grinding-equip.com

Address: No.19 Fuqing Rd, Pudong New Area, Shanghai201201, China.

Through long-term arduous technology research and international communication, our product quality has been in line with international level, winning a world-wide acclaim and honor, and our products are exported to ninety countries and regions like Tanzania, Nigeria, South Africa, Kenya, Turkey, Saudi Arabia, Philippines, Indonesia, Malaysia, Vietnam, Mexico, Brazil, Russia, Uzbekistan, Australia, etc.

Please feel free to write down your requirement in the form below.

We will reply you within 24 hours.

Copyright: Shanghai Clirik Machinery Co., Ltd.All rights reserved