Clirik, in pursuit of efficient and environmentally friendly industrial production, recognizes the importance of ultra-fine powder preparation technology as a measure of a company's technical prowess. Leveraging its extensive experience in mill production and sophisticated German ultra-fine vertical mill technology, Clirik has successfully developed the CLUM series ultra-fine vertical roller mill. This groundbreaking equipment combines grinding, classification, conveying, secondary air separation, and finished product packaging into one system, thus revolutionizing the global market for ultra-fine powders.

The CLUM series mill from Clirik provides an advanced powder processing solution. It excels in performance and features a detailed process flow. Initially, raw materials enter the mill's main unit via a belt scale, elevator, and conveyors for grinding. The ground powder is separated and collected by a dust collector, then transported to the product bin by conveyors and a gas machine, ready for packaging.

A small amount of oversized particles from the vertical mill main unit are re-grinded after being returned to the mill by a return screw conveyor, ensuring the uniformity and fineness of the powder. Moreover, the belt scale with a magnetic separator not only accurately controls the feed amount but also effectively filters metal impurities in the raw materials, ensuring the stable operation of the vertical mill and product quality.

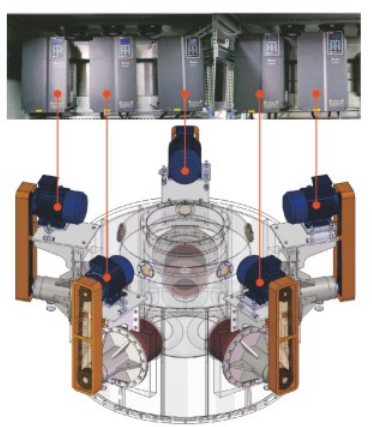

Clirik meets high particle size and 2μm content demands with CLUM series. We center the secondary air separation process on an ultra-fine classifier. It includes a transfer bin, elevator, fan, airlock discharger, pipelines, dust collector, screw conveyor, and gas conveying machine. This complete system meets various customer needs for ultrafine powders.

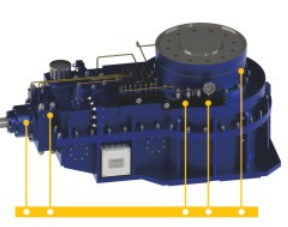

Use the special anti-wear alloy materials for grinding roller and plate liner. Long service time for wear parts, low maintenance.

It has greatly increased the final powder added value and application areas due to the advantages of narrow particle size distribution, unit form particles shape and controllable 2 micron content.

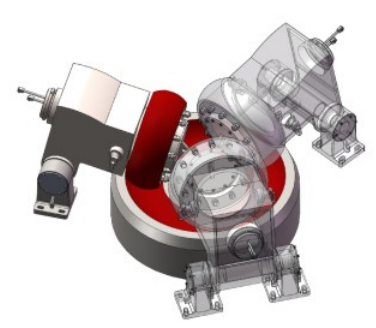

The grinding roller's pressure is auto-controlled by the PLC/DSC system. This automation allows for the precise application of grinding pressure. As a result, the process achieves high efficiency without the need for manual operation.

The environment is clean, meeting the national environmental protection requirements.

Clirik leads in ultra-fine mill tech. Over 30 production lines built globally. Proves our gear's reliability and edge. Interested in top powder tech? Consult us. See how CLUM series boosts efficiency, quality. Clirik: your go-to for ultra-fine solutions.

上一篇: High Efficiency And Low Cost Ultra-fine Vertical Mill

下一篇: What are the non-metallic mineral ultra-fine grinding equipment

Please feel free to write down your requirement in the form below.

We will reply you within 24 hours.

Copyright: Shanghai Clirik Machinery Co., Ltd.All rights reserved